By :

Novozymes and Buhler

Gristing Wheat

The key step in the quality process is the blending of wheat known to

the miller as the “wheat grist”. Based on the type of flour and

characteristics, the miller decides which wheat and in what proportions should

be used in the grist.

The grist for a flour is chosen by a variety of methods. But it is

generally based on the miller’s experience, wheat quality characteristics and

knowledge of the customer’s process and needs.

Blending wheat prior to milling is a very popular way of producing

flours but it does have some disadvantages. Each wheat grain in a grist has its

own irregular characteristics, depending on its variety or source, such as

grain size, shape, hardness, moisture content, protein quality, and quantity.

These characteristics may affect the way the grain performs through

the mill. So if the grains are blended before milling, the mill settings have

to be a compromise between the various milling characteristics.

In case the

wheat varieties to be mixed are quite different in hardness, it is advisable

they are cleaned and conditioned separately to achieve the same softness at first break. If different kinds of wheat are milled individually, the produced flour

batches are blended.

Grinding Wheat

Wheat grinding involves a series of breaking rolls, graders

(plansifters), purifiers and reduction rolls.

Usually the break system consists of 4 to 5 passages, supported by

additional bran finishers. The target of the break system is to separate the

bran from the endosperm as efficiently as possible, producing clean

intermediate products and minimizing the production of flour at the same time :

• Four break passages are required when grinding hard wheat varieties or for achieving extraction rates of up to 76%

• Four and half to five breaks are suitable for soft wheat varieties or extractions between 76-80%. Should the extraction have to be higher than 80%, an extra passage or the so called “bran grinding” passage, has to be foreseen as well

To obtain a better grinding work at the last two break passages, they

are split into coarse and fine in medium to large size mills.

Depending on the

type and extraction of flour to be produced and the type of wheat to be milled,

in terms of hardness, every bran stream (coarse and fine) has to be passed over

bran finishers at least 1-3 times.

The breaking of wheat is done with rolls that crush the kernels

spinning toward each other at a high speed rate.

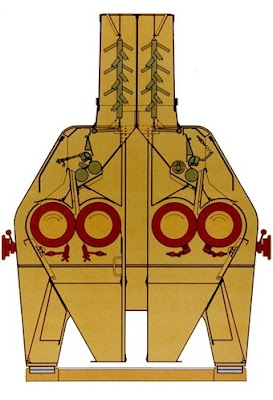

|

| Cross section of a roller mill (Picture is a courtesy of Buhler AG, Uzwil, Switzerland) |

The break stock has to be graded according to size. This process is

already started in the break sifters. Most commonly additional sifter sections,

or the so-called “graders” or most commonly “plansifters” are required to

complete this process.

The plansifter is a stack of sieves of decreasing mesh

size that separate particles by size.

The number of plansifters is determined by the size of the mill,

maximum number of sieves per sifter section, and number of granulations (groups

of products of the break stock) applied.

The graded product streams – leaving the break sifters and graders –

still contain bran particles. These bran particles cannot be separated from the

endosperm particles due to their similarity in size.

With the help of air,

purifiers can further group these different granulations into clean endosperm

particles; endosperm with bran particles still adhering (composite stock); and

bran pieces.

For high yields of low ash flour, it is necessary to purify the semolina

and middling before they are further reduced. If semolina and middling are the

desired finished products, then the use of purifiers is absolutely necessary.

The

number of purifier passages depends on the amount of low ash flour to be

produced – whether semolina or middling is to be sold or not – the type of

wheat to be milled (the harder the wheat, the more important is purification).

|

| Cross section of Purifier (Picture is a courtesy of Buhler AG, Uzwil, Switzerland) |

The composite particles obtained from different purifiers, have to be

treated by rolls again. The scratch rolls (smoother than the breaking rolls)

treat the composite stock in such a manner, that the adhering pieces of bran

can be efficiently separated from the endosperm.

Depending on the importance of

producing a high amount of low ash flour or also on the amount of semolina

required, this process can be completed with more or less pressure or care.

The number of scratch passages can vary between one and two and

depends on the importance paid on the process (finished products) as well as on

the size of the mill.

The purpose of the reduction system (series of even smoother rollers)

is a more or less careful reduction of semolina and middling into flour.

This reduction

has to be done in several steps to achieve a finished product whose baking

characteristics do not get worse by overheating and also to be able to produce

products with different ash values and granulations.

The number of reduction

passages is determined by the hardness of the wheat to be milled, granulation

of the flour to be produced, and extraction of flour.

The bran finisher removes adhering flour particles from the bran, thus

increasing flour yield at the mill. This is achieved using slanted beaters that

give the tangentially incoming material stream an additional axial motion

improving the yield of flours.

Blending Wheat Flour

The flour after milling is stored in storage bins usually made of reinforced concrete or steel. from there, it is either transferred directly to the packing line or mixed with other flours and ingredients to achieve the desired quality characteristics.

In the past, grain gristing (mixing) was used based mainly on equal wheat hardness. however, if the capacity of flour mixing equipment is adequate it is no longger necessary. Flour blending can be done by the following means :

• continuous, volumetric dosing and mixing

• continuous, gravimetrical dosing and mixing

• batch mixing system

The continuous volumetric system can be applied, if no high demand in regards to mixing accuracy is necessary. Frequency converters control volumetric bin dischargers. the desired mixing ratio can be adjusted by selecting the speed of the bin dischargers.

Screw conveyors collect the continuously discharged flours and lead them to a pneumatic lift. The volumetric mixing system should only be applied, if larger batches of mixes have to be produced.

During every start up or stopping period, an increased inaccuracy of the mixture may be noticed, because not all the discharges might reach full operation at the same time.

An additional problem in terms of accuracy could arise, if the bulk density of different types of flour keeps changing. This simple installation however, can be an economical solution for mixing flour at a high capacity.

When large batches of flour mix with a relatively low number of components have to be produced, the continuous, gravimetrical dosing and mixing system should be applied.

The basis of this system is the continuous weight recording and regulation of the through-flow capacities with a following homogeny mixing of the continuously arriving product streams.

Continuously working scales, which are installed below the flour bins, join together the different types of flour at a selected flow rate. Chemical feeders can be additionally installed for the continuous addition of the micro ingredients.

A homogenizer mixes the arriving products into a uniform mix. Every component of the mix requires an independent scale. The scales are controlled via a computer program, which contains different recipes for the mixes.

Such a system is favored because it facilitates accurate blending of the main and special flours, small ingredients according to recipe, especially suitable for lot sizes of 10 to 100 t and higher and easy alteration of capacity.

If a large number of different flour types have to be produced, a batch mixing plant can offer several advantages :

• increased flour yield, due to the possibility of separate milling of differing wheat varieties in regards to the degree of hardness

• Milling of larger wheat quantities of the same grist, resulting in less grist changes and therefore, less labor work and less off-grade flour, which is produced during grist changes

• Better flour storage bins utilization

• High accuracy of the flour blending due to dosage by weight

• More flexibility concerning flour varieties or just in time deliveries

• Possibility of correcting mistakes made in the cleaning or grinding section with little effort

• Mixxing a small lots of even 500kg

• Easy extension of the flour assortment, therefore, very flexible to meet special customer requirements

• Lower investment costs if a large number of different flours and ingredients have to be mixed

• Reduction of mixing time, due to the application of high speed mixers

With the batch mixing system, the different compounds of a mixture are weighed and accumulated in the batch scale. After completion, the batch is filled into the mixer.

When mixing is over, the content of the mixer is dropped into a hopper and transported to the packing or loading bins. All this is a discontinuing process. The following four steps are included in one mixing cycle of a batch mixer :

• Preparing the different types of flour components and additives by weight according to the recipe

• Emptying the scales into the mixer and mixing

• Emptying of the mixer

• Transporting the batch into storage, packing or loading bin

If the amount of flour mixes to be produced is rather small and the addition of micro ingredients rather seldom, micro components could be added manually. Under normal conditions however, it is worthwhile to install a system to add the micro ingredients.

Such an installation serves the purpose of storing the micro ingredients, feeding them to a small scale, registering the weight as well as feeding ingredients to the batch.

Given that we have to deal with rather small quantities of micro ingredients, they can be filled manually into the small storage hoppers. Most of the micro ingredients have very bad flowing characteristics. Special discharging and dosing units are, therefore, required.

Packing Wheat Flour

To be sure that no foreign objects remain in the flour, a rotary sifter should be installed ahead of the packing unit or bulk out-loading system.

Depending on the capacity, the granulation and the flowing characteristic of the flour, sieve openings between 1.0 to 3.0 mm have to be selected. Metal detectors further boost product safety.

For destroying insect egss, sterilities can be installed prior to the packing system. Finally, flour is packaged either in bags or silo trucks.

|

| Wheat Flour |

Great job for publishing such a beneficial web site. Your web log isn’t only useful but it is additionally really creative too.

ردحذفcheck these links for more relevant content related to your blog

Forex Market

Financial Market

Currency Pairs

Currency Trading

That's a great article and detail regarding the stocks. What are the habits of good investor? and how to pick a right investment option?

ردحذفall types of stocks

Marico

best franklin templeton mutual fund

ujjivan financial services

analyst estimates

what is the stock market

mutual fund news

hindalco share price

Nice Blog and Good information. I will try to add

ردحذفHow much do I expect to earn on stock investment?

rpg life sciences

ashok leyland share price target

what is nifty

sell on infibeam

adani port share price

short term stock recommendations

berger share price

sundaram mutual fund

Good Article. Thanks for sharing such greatful information.

ردحذفEquitas Holdings Limited

IRCTC IPO

NTPC Ltd

Ola IPO

ردحذفHello,

If you want to go into wheat farm business, There are so many company website this days like http://www.virtatrade.com that will enable you as a beginner to raise the fund you need to start up your wheat farm business without you seeking for a loan.

This company is where many business dealers from all over the world generate fund that backup their various businesses financially.

I used this company to backup my cocoa beans export business each time am running loss financially.

You can visit and register with the company website here http://www.virtatrade.com to raise the fund you need now to go into your wheat farm business now.

إرسال تعليق