Wheat evaluation in the United States is undertaken to ensure general

standards of acceptance in flour or semolina production. Many factors are used

to determine the wheat class and grade. Physical attributes including colour, shape

and hardness determine the class of wheat and the inclusion of contrasting wheat

classes. The presence of dockage, foreign material and damaged kernels attests to

the overall wheat quality. Test weight provides an indication of kernel

soundness and suitability for milling. While factors determining wheat grade

are important, they do not completely describe wheat quality.

Wheat quality factors not included in the grading system are

critically important to grain storage and milling and baking performance. Moisture

and protein content are among the most obvious of these characteristics. Maintaining

wheat quality depends on monitoring and controlling moisture content in a safe

range. Protein level is often a key characteristic in selection by the miller

for the production of bakery flour. Enzymatic (amylase) activity is also an

important characteristic of wheat that must be monitored

and measured.

Wheat is often milled to produce flour for these tests on automatic

and continuous laboratory-scale milling units such as the Brabender Quadrumat

Jr. and Senior and Buhler laboratory mills. Wheat may also be milled for evaluation

using a host of walking flows which incorporate small-scale standalone roller

mills and sifters in a batch milling process. These laboratory mills do not completely

duplicate the gradual reduction milling processes used in the commercial milling

industry. They do however provide the opportunity to rank wheat milling performance

and produce flour for further testing and evaluation. Laboratory milling can

provide an insight into the milling characteristics of wheat, including bran

clean-up, endosperm reduction properties and of course flour yield.

Flour from laboratory milling is often subjected to other testing to

determine quality and suitability. Beyond the protein level there is the issue

of protein quality, measured by a variety of physiochemical and dough rheology tests

including wet and dry gluten, Farinograph, Alveograph, and a host of other recording

dough mixers and manipulative tests. While these additional tests may reflect bakery

performance and the properties of the finished baked goods, they too fail to

describe wheat quality completely.

The final arbiter of wheat suitability and performance is the baking

test or, in the case of durum wheat, pasta production and preparation. A laboratory

baking test has been established to measure flour performance characteristics

in a controlled environment. The formulations do not usually reflect a specific

commercial product, but rather the product's principle components at a level that

maximizes the influence of flour quality on finished product performance. As with

laboratory formulations, the laboratory process does not reflect all possible combinations of factors that one might

experience in the commercial bakery. The goal of these procedures is to control

and minimize sources of variation so that changes in finished product quality can

be attributed to flour characteristics. Below is a summary of U.S. wheat

classes and key performance factors for 1999 – 2004 (Tab. 10).

|

Tab. 10: Summary of key performance factors of U.S. wheat classes 2000

- 2004 a

|

|

Fig. 13: Processing the working wheat sample (courtesy of USDA-GIPSA –

Grain Inspection, Packers and Stockyards Administration, Washington, D.C.)

|

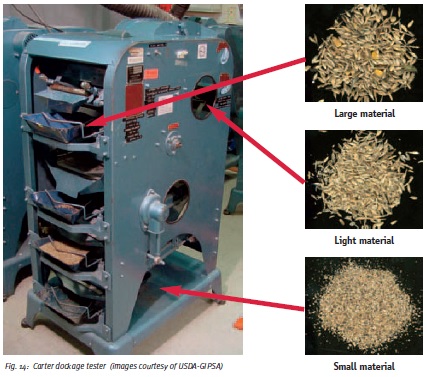

1. Dockage

Dockage is considered to be material other than wheat that can be

easily removed (as opposed to Besatz 5). It is determined with a special

machine called the Carter Dockage Tester (Fig. 14). In the U.S. grain grading system,

dockage does not influence the numerical grade. It is important as the first step

in the grading process because the dockage is removed prior to test weight measurement.

It is also important in describing the condition of the wheat, and the percentage

of dockage is therefore recorded on the certificate by the inspector. Using

aspiration (air) and a combination of riddles and sieves, the Carter Dockage

Tester prepares a sample for grading by removing the readily separable material.

Generally speaking, this material consists of all matter that is lighter than,

larger than, or smaller than wheat. The material removed by a dockage tester is

readily separated and does not require the additional sophisticated equipment

found in the mill's cleaning house.

Note :

5 While dockage is the result of a standardized screening process,

the term Besatz comprises all components of a grain sample which are not

perfect grain of the target species. Besatz is determined by ICC standard

methods 102/1 (wheat) and 103/1 (rye).

Following dockage removal, the test weight of the wheat is measured. Test

weight per bushel is the weight of the grain required to fill a level Winchester

bushel measure with a capacity of 2,150.42 cubic inches (35.24 L). The factor

"test weight per bushel" is determined using an approved apparatus,

which has a kettle capacity of one dry quart (1.101 L). This determination is made

on the basis of 1,350 g of wheat cut from the representative sample using a

Boerner Divider. To determine test weight, the work sample is poured into the

closed hopper centred over the kettle. The valve is quickly opened to allow the

grain to fill the kettle. A standard stroker held in both hands with the flat

sides in a vertical position is used to remove the excess grain from the top of

the kettle with three full-length zigzag movements. The kettle is carefully

placed on the scale platform. The weight is read by an electronic scale that

converts the gram weight to either pounds per bushel or kg per hectoliter (Fig.

15). Test weight per bushel is a grading factor and will therefore influence

the numerical grade of a wheat sample. In the U.S. it is generally expressed in

pounds per Winchester bushel, but upon request it can be converted and reported

in kg per hectolitre.

3. Examining for Sample Grade

Factors

Sample grade factors are f.i. animal filth, glass, stones, toxic seeds

and unknown foreign substances. Special grade factors include ergot, smut,

garlic, and treated seed (Fig. 16).

4. Examining for Special Grades

Special grades are provided to emphasize special qualities or

conditions affecting the value of wheat and are added to, and made a part of,

the grade designation. There are six special grades in wheat. Definitions and examples

of the designations for special grades in wheat include:

Ergoty Wheat

Wheat that contains more than 0.05% of ergot.

Garlicky Wheat

Wheat that contains more than two green garlic bulblets or an

equivalent quantity of dry or partly dry bulblets in a 1,000 g portion.

Infested Wheat

Wheat that is infested with live weevils or other live insects

injurious to stored grain.

Light Smutty Wheat

Wheat that has an unmistakable odour of smut or which contains, in a

250 g portion, smut balls, portions of smut balls, or spores of smut in excess

of a quantity equal to 5 smut balls, but not in excess of a quantity equal to 30

smut balls of average size.

Smutty Wheat

Wheat that contains, in a 250 g portion, smut balls, portions of smut

balls, or spores of smut in excess of a quantity equal to 30 smut balls of

average size.

Treated Wheat

Wheat that has been scoured, limed, washed, sulphured, or treated in

such a manner that the true quality is not reflected by either the numerical

grades or the U.S. Sample grade designation alone. Special grades do not affect

the numerical or sample grade designation.

5. Shrunken and Broken Kernels

At this point, all tests required to be performed prior to the removal

of dockage have been made and the percentage of dockage has been determined.

The sample has also been test-weighed and examined for certain sample grade and

special grade factors. Now the work portion is ready to be divided into

fractional portions for other determinations required after the removal of

dockage. When testing wheat for shrunken and broken kernels, cut out a 250 g

portion for shrunken & broken (SHBN) using the Boerner divider. SHBN

kernels consist of all matter that passes through a 0.064 × 3/8 oblong-hole

sieve after sieving using either the "Mechanical Sieving Method" or the "Hand

Sieving Method". Mechanical sieving is preferred to the hand-sieving method

because the results are more uniform and accurate in counting the number of strokes.

All material that passes through the sieve is considered shrunken and broken

kernels. Return the material lodged in the perforations to the wheat that has

remained on top of the sieve. To remove the lodged material from the perforations,

rub the sieve bottom gently. Tapping will warp the sieve and lead to inaccurate

results in future determinations. At this point, the percentage of Shrunken and

Broken has been determined. The material is weighed to the nearest tenth

percent and recorded on the grade certificate. Now the SHBN-free portion is

ready to be divided into fractional portions for other determinations required

after the removal of SHBN.

6. Foreign Material

Foreign material or FM consists of all matter other than wheat that

remains in the sample after the removal of dockage and shrunken and broken

kernels (Fig. 16A). Determine foreign material on a dockage-free and

shrunkenand- broken-free portion of 50 g. Other grains including oat groats,

hull-less oats, glumes on threshed or unthreshed kernels, and all matter other

than wheat are considered foreign material and removed from the portion. Remove

the glumes from the kernels of wheat and add to the foreign material. The

foreign material is expressed as a percentage by weight of the total sample.

Record the percentage of foreign material on the certificate to the nearest

tenth percent.

7. Damaged Kernels

Determine damaged kernels on a dockagefree and shrunken-and-broken-free

portion of 15 g. Damaged Kernels Total or DKT is kernels, pieces of wheat

kernels, and other grains that are badly ground-damaged, badly weatherdamaged, diseased,

frost-damaged, germdamaged, heat-damaged, insect-bored, mould-damaged,

sprout-damaged, or otherwise materially damaged. In general, a kernel of wheat

and/or kernels of other grains are considered damaged for inspection and grading

purposes only when the damage is distinctly apparent and of such character as

to be recognized as damaged for commercial purposes (Fig. 16).

Black Tip Damaged Kernels

Kernels affected by black tip fungus to the extent that the discoloration

(fungus growth) extends beyond the germ and continues around at least one cheek

and into the crease are considered damaged. All conditions MUST be met to be

considered damage. The illustration shows, from left to right (Fig. 16K):

Kernel 1: The minimum

degree of discoloration and amount of coverage required on the germ.

Kernel 2: The minimum

degree of discoloration required in the "continuous band" that extends

around the cheek. The width of the band is irrelevant.

Kernel 3: The minimum

degree of discoloration required extends into the crease. The amount of

discoloration (area of coverage) is immaterial.

Blight or Scab Damaged Kernels

Kernels with a dull, lifeless and chalky appearance resulting from

disease are considered damaged. The germ and crease may also have a mouldy appearance.

The illustration (Fig. 16L) shows a kernel affected by scab to the extent that it

has a dull, lifeless, chalky appearance (not a natural wheat colour). Such kernels

are scab-damaged without further examination.

Frost Damaged (Blistered) Kernels

Kernels that have blisters due to frost areconsidered damaged. The

illustration (Fig. 16M) shows kernels with distinct frost blisters extending around

the back of the kernel and into the crease.

Germ Damaged (Sick) Kernels

Kernels damaged as a result of microbial activity but not materially

discoloured are considered damaged (Fig. 16N). Sick kernels should be scraped

very carefully to avoid the loss of discoloration and/or "popping" or

removal of the germ. Kernels and pieces of wheat with discoloured germs that

are as dark as, or darker than, shown are to be considered damaged.

Germ Damaged (Mouldy) Kernels

Kernels which have mould in the germ are considered damaged. The bran

coat covering the germ should be removed carefully, as scraping the bran coat

too deep might remove the mould. Fig. 16O shows a kernel of wheat with a mouldy

germ.

Green Damaged (Immature)

Kernels that are of an intense green (immature) and without any yellow

appearance are considered damaged. Fig. 16P shows kernels that are green (immature)

in colour. The green colour must meet the minimum intensity shown on BOTH sides

of the kernel. Also there should be no yellow cast showing through the green.

Heat Damaged – Durum

Kernels materially discoloured and damaged by microbial activity are

considered damaged. It is necessary, in most cases, to cut the kernels and make

a cross-section analysis to determine whether the colour is reddishbrown, mahogany,

or creamy. Fig. 16Q shows:

Kernel 1: An example of a

kernel that should be cross-sectioned to determine whether it meets the minimum

discoloration requirements depicted by Kernels 2 and 3.

Kernel 2: The degree of

discoloration required in a cross-sectioned vitreous kernel.

Kernel 3: The minimum

discoloration (cream) required in a cross-sectioned non-vitreous (chalky)

kernel to be considered heat damaged.

Heat Damaged – Other than Durum

Kernels materially discoloured and damaged by microbial activity are

considered damaged. It is necessary, in most cases, to cut the kernels and make

a cross-section analysis to determine whether the colour is reddishbrown,

mahogany, or creamy. Fig. 16R shows:

Kernel 1: An example of a

kernel that should be cross-sectioned to determine whether it meets the minimum

discoloration requirements depicted by Kernels 2 and 3.

Kernel 2: The degree of

discoloration required in a cross-sectioned vitreous kernel.

Kernel 3: The minimum

discoloration (cream) required in a cross-sectioned non-vitreous (chalky)

kernel to be considered heat damaged.

Sprout Damaged

Kernels with the germ end broken open from germination exhibiting

sprout or from which the sprouts have been broken off are considered damaged.

Fig. 16T shows, from left to right:

Kernel 1: The sprout is

broken off leaving part of the germ cover over the socket area.

Kernel 2: The sprout is

broken off leaving no germ cover over the socket area. Sprout sockets typically

have bran around the perimeter of the germ that resembles a "horse

collar".

Kernel 3: The germ cover is

broken open with a sprout showing at the bottom. Notice that the sprout flares

out towards the bottom of the germ area.

Kernel 4: The germ cover is

broken open with a sprout showing at the top. The sprout has lifted upward leaving

a spade between the sprout and germ cavity.

Mould-Like Substance

Whole kernels of wheat that are 50% or more covered and pieces of

kernels that are discoloured and covered with a mould-like substance are

considered damaged. Fig. 16U shows mould or a mould-like substance on a wheat

kernel.

Other Damage

Kernels with cracks, breaks or chews and which contain mould or fungus

are considered damaged. Fig. 16V shows, from left to right:

Kernel 1: Broken kernel

containing mould.

Kernel 2: Split bran coat

containing mould.

Kernel 3: Insect-chewed

kernel containing mould.

Insect-Bored

Kernels that have been bored or tunnelled by insects are considered

damaged. Fig. 16W shows from left to right:

Kernel 1: Kernel that has

been tunnelled.

Kernels 2 &3: Kernels

that have been bored.

8. Total Defects

Total Defects is the sum of damaged kernels, foreign material and

shrunken and broken kernels. The sum of these three factors may not exceed the

limit for the factor defects for each numerical grade. Determine defects by the

sum of damaged kernels, foreign material, and shrunken and broken kernels. A

percentage

for defects cannot be shown if only one or two of the factors defined

as defects have been determined. However, if one or two factors are determined

and their sum would change the numerical grade, or come close to changing the grade,

determine the other factor and record the percentage of defects (Fig. 16J).

Record the percentage of defects on the certificate to the nearest tenth

percent. If the percentages for

damaged kernels, shrunken and broken kernels and foreign material are

added together and the total exceeds one hundred percent, adjust the percentage

of defects by adjusting the damaged kernels (total).

Post a Comment