Wheat, the "Staff of Life", has been an essential commodity

to human existence through the centuries and is currently the most widely

consumed staple food (Bagriansky, 2002). As versatile as they are nutritious,

wheat products have graced tables in all continents.

The range of forms this

staple food takes is correspondingly varied: crusty French bread, soft Mexican

tortillas and spicy Indonesian noodles being a few examples.

Fortunately for

wheat eaters, wheat flour naturally contains many nutrients essential to human

growth and development (Ranum and Wesley, 2003).

Wheat is important not only to stimulate appetite; it also plays an

important role in ending "hidden hunger". "Hidden hunger"

is caused by subtle vitamin and mineral inadequacies which show themselves over

time in the reduced productive capacity of individuals and nations (Gautam,

2003).

Vitamin and mineral deficiencies cause "hunger" because the

body will wither and die without the necessary levels of these nutrients. This

hunger is "hidden" because vitamin and mineral deficiencies do not

stimulate the appetite.

Approximately 2 billion people throughout the world are affected by

"hidden hunger". Two of the chief nutrient deficiencies causing

"hidden hunger” are those of iron and folic acid.

These nutrients are

essential for mothers to give birth to healthy babies and for children to reach

their full intellectual and physical capabilities.

Because of flour processing,

which reduces the natural level of iron and folic acids, and many peoples'

inability to consume balanced diets, people in many countries who consume large

amounts of flour suffer from iron and folic acid deficiencies.

These deficiencies

cause paralyzing birth defects and reduce the ability of children to learn and

of adults to work hard (Gautam, 2003).

Flour enrichment and fortification play key roles in correcting these

deficiencies, restoring health and economic growth to nations, through boosting

the nutrient levels in flour.

In the words of Mr. Kul C. Gautam, Deputy

Executive Director of the United Nations Children's Fund in his address to the

International Grain Conference 2003, "You have the power to help improve

the learning ability, productivity and prosperity of millions of consumers

around the world by supporting the fortification of cereal flours with

essential micronutrients" (Gautam, 2003).

Flour millers have the

opportunity to join in this noble mission, ensuring that all babies have the

same chance of a healthy start to life.

2. Iron

Iron is present in every cell in the human body, and plays a vital

role in red blood cells by helping to carry oxygen through the body. People can

be mildly to severely deficient in iron. All levels of deficiency affect the

function of the human body (Gleason, 1998 and 1999).

In a severe form, iron

deficiency results in anaemia, a condition in which the body does not have

enough red blood cells and cannot function at full capacity.

Although most

anaemia is caused by iron deficiency, it can sometimes be caused by other

vitamin deficiencies such as vitamin A and vitamin B12.

The reduced capacity

caused by anaemia manifests itself in lower work productivity in men and women,

decreased intelligence in children, and greater risk of low-birth-weight babies

in pregnant women.

Women and children are most at risk for iron deficiency

because of their high blood loss and rapid growth respectively (Anon., 1998).

Iron deficiency is the most common nutritional deficiency in the

world. The World Health Organization (WHO) estimates that 40% of the world's

population is anaemic (Anon., 2003); in 75% of all cases this is due to severe

iron deficiency (Ramakrishnan, 2001).

The cost of anaemia to the economy is

high: a nation loses approximately USD 4 per capita per year for every

individual with iron deficiency. South Asia is thought to bear these losses

most heavily, losing as much as USD 5 billion annually (Ross and Horton, 1998).

The prevalence of iron deficiency varies throughout the world, but it

is highest outside the Americas and Europe. Tab. 81 describes anaemia

prevalence as a marker for iron deficiency.

|

| Tab. 81 : Blood anaemia rates by region of the world a |

3. Folic Acid

The vitamin folate enables cell division and tissue growth. Folate is found only in small amounts in wheat, higher levels being contained in a variety of fruits, vegetables, and legumes (Gibbson, 1990).

Folic acid is a synthetic form of folate which is used in food fortification and is more easily absorbed by the body than natural folates (Anon., 2000).

Since 1991, scientists have discovered that folic acid consumed at high levels is important for preventing disabling neural tube birth defects and has a significant potential for preventing heart attacks and strokes as well as colon cancer.

The protective levels of folic acid described in these studies were primarily consumed through the use of multivitamins, not through consumption of normal, non-fortified diets (Anon., 1991a and 1991b; Giovannucci et al., 1998; Rimm et al. 1998).

Globally, 300,000 children are born each year with neural tube defects (Oakley, 2002). This is equivalent to the number of global polio cases which sparked the well-publicized polio eradication campaign in 1988 (Oakley, 2003).

Neural tube birth defects occur when skin and bone do not form correctly around the brains and spinal cords of foetuses at about 20 days post conception. These defects lead to brain and spinal cord damage which leaves children paralyzed, incontinent, or without parts of their brains (Behrman, 2000).

Of the 300,000 children born with these debilitating defects, 200,000 defects each year could be prevented through mothers consuming higher levels of folic acid (Oakley, 2002).

Folic acid fortification of flour increases maternal consumption of folic acid and has been shown to decrease the number of children born with birth defects in the USA and Canada by 19% and 48% respectively (Anon., 2003b, Honein et al., 2001 and Persad et al., 2001).

4. Nutrient Loss in Flour Processing

Iron and folic acid are among the vitamins and minerals lost when bran and germ are separated from endosperm. Flour extraction therefore determines the levels of iron and folic acid in the flour. The higher the flour extraction, the greater are the remaining levels of iron and folic acid.

The nutritional content of high-extraction flour is complicated by the presence of natural phytates in the flour which also exist in higher levels in high-extraction flour.

These phytates prevent the body from absorbing most of the wheat's iron and folic acid (Ge et al., 2001 and Hurrell, 1997). Thus, the unique health benefits of high extraction or "whole wheat" flour do not extend to increased iron and folic acid available to the consumer.

Like iron and folic acid, many vitamins and minerals contained in flour are diminished during the flour refinement process.

As discussed above, the vitamins and minerals found in flour are not naturally highly bioavailable, meaning that they are not usually available for absorption by humans (Hurrell, 1997).

The vitamin and mineral content of whole wheat and refined flour is illustrated in Tab. 82 for the quantities of iron, folic acid and several B vitamins found in 170 g of flour.

|

| Tab. 82 : Vitamin and mineral daily intake from wheat and white floura,b |

This table demonstrates the effect processing to make white flour has on the nutritional content of the flour. Flour processing decreases the levels of naturally occurring, non-bioavailable nutrients in flour.

As an example, this table shows that the average American man can consume a large amount of non-bioavailable iron through whole-wheat flour without meeting his daily needs.

The folate naturally contained in flour is also less available for absorption than the type of folate, folic acid, which is added during fortification (Anon., 2000).

So enrichment and fortification replace iron and folic acid in the flour in a form that the body can absorb and use.

Bulk production of flour in industrialized countries as well as in many economically less developed countries entails the production of white refined flour. The processing and end product quality of a vast majority of the products made from wheat flour requires the use of this white refined flour.

There are various levels of refinement of white flour that may be specific to a company, country or region; however, an extraction rate of 75% for white flour is generally considered an average figure for most of these situations. This means that approximately 25% ends up in animal feed.

FFI acts on the assumption that fortification is an industrial process which occurs in a flour mill.

In addition, what flour millers choose to add to milled flour is influenced by a variety of factors including the government, the scientific health processing, and the beliefs of the flour miller about what is best for the consumer.

5. Current National and Regional Fortification Programmes

Many governments and in some cases private enterprises or individual companies have adopted some kind of wheat flour fortification programme.

At the UN Special Session on Children in 2002, nations were asked to improve children's nutrition through a number of mechanisms including food fortification (Anon., 2002), and forty-eight countries are currently enacting fortification programmes through voluntary or mandatory legislation (Fig. 101).

|

| Fig. 101 : Percentage of countries in each region with national mandatory or voluntary flour fortification programmes |

Twenty-eight of these countries fortify with iron and folic acid. Through the efforts of these governments and the private milling industry, 15% of the approximately 400 million tons of flour consumed each year is fortified with these essential nutrients (Nystrom, 2003).

In response to the low percentage of total flour fortified every year and the severe global problem of iron and folic acid deficiency, the Flour Fortification Initiative (FFI) was inaugurated in May 2002.

FFI is sponsored by the Micronutrient Initiative based in Ottawa, Canada, the Centres for Disease Control and Prevention in Atlanta, Georgia, and the United Nations Children Fund. Its goal is to move flour fortification ahead in parts of the world in which it would be beneficial for human health.

The following are examples of regional standards proposed by various groups (Tab. 83):

|

| Tab. 83 : Current fortificant level guidelines by region a |

FFI acts on the assumption that fortification is an industrial process which occurs in a flour mill.

The USA and Canada fortify at the following levels (Tab. 84):

|

| Tab. 84 : Fortificant guidelines of the USA and Canada a |

In addition, what flour millers choose to add to milled flour is influenced by a variety of factors including the government, the scientific health processing, and the beliefs of the flour miller about what is best for the consumer.

As flour milling is influenced by a variety of public, private, and civic organizations, FFI seeks to build partnerships between these sectors. So flour fortification moves forward through agreement between all the partners on the benefits and cost effectiveness of flour fortification.

FFI considers the following to be important for an effective fortification programme:

• Use of iron and/or folic acid as a minimum

• Use of roller flour mills producing refined white flour with an extraction rate of less than 82 percent

• Collaboration with existing national fortification efforts

• National determination of fortifications and fortification levels

Advocacy of current guidelines published by international public health agencies with the nutritional goal of providing 400 μg per day of folic acid per person and restoring iron in flour at least to pre-milling levels.

Most of the current flour fortification programmes involve restoration of iron and other nutrients in the flour to the same raw level as was present in the original grain. This is done, in part, to preserve the quality of the finished flour product.

Folic acid, however, is fortified above the level normally found in grain, since the usual grain raw folate levels are too low to prevent birth defects.

Other factors that determine which fortification levels a nation or company chooses include the nutrient deficiencies present in the population, how much flour a population consumes, the cost of the premix, and the fortification guidelines of primary trade partners (Ranum and Wesley, 2003).

For country guidelines, please see

6. Flour Consumption and Fortification Benefit

Some people question whether many countries with high levels of iron and folic acid deficiency consume enough flour for flour fortification to be effective at preventing severe deficiencies.

The answer is that flour fortification is only one arm of the strategy for controlling nutritional deficiencies: dietary diversification to include foods with high concentrations of nutrients and iron and folic acid tablet distribution to vulnerable members of society are also important.

These two other arms are necessary as flour fortification only delivers part of a person's recommended daily allowance of nutrients and thus cannot be used alone to treat individuals with severe nutritional deficiency.

In addition, the members of society with the most severe iron and folic acid deficiency are often the most socioeconomically disadvantaged (see Fig. 102) and thus do not consume large quantities of fortified flour (Darnton-Hill et al., 1999).

However, the members of a population with the most severe forms of iron and folic acid deficiency are not the only members of the population who are deficient.

For example, anaemia in a population is only the tip of the iceberg, a sign that there are many more members of the population who are iron-deficient (Ramarkrishnan, 2001).

|

| Fig. 102 : Benefit of flour fortification to populations by socioeconomic status (Darnton-Hill, 1999) |

Flour fortification protects the bulk of a nation's iron- deficient population, those who are able to afford the flour. The protection given them by the flour can prevent them from becoming anaemic in times of biological stress (Darnton-Hill, 1999).

For example, a woman is more likely to become anaemic during pregnancy (vulnerable state) if she has mild iron deficiency before she becomes pregnant. Flour fortification can raise her normal level of iron and thus prevent serious deficiency during pregnancy (Salgueiro et al., 2002).

There are also other types of fortification directed towards economically and physiologically disadvantaged groups. South Africa is employing one such type of targeted fortification.

During the initial food consumption analysis it was discovered that maize was consumed primarily by the members of society on the lower socioeconomic levels, and wheat by the higher socio-economic classes.

The Republic of South Africa now fortifies both types of flour in order to fully cover the population (Bargriansky, 2003).

In addition, baby food and baby formula is fortified at high levels in many countries in order to supplement the nutrient intake of children (Anon., 2002b) In the US, fortification of baby food and formulas has reduced anaemia rates in children under 2 to very low levels (Anon., 1998a).

Boosting of a population's usual iron consumption with general flour fortification translates into decreased numbers of people with anaemia over time, and decreased anaemia results in economic benefit for a nation.

Only 52 of the approximately 189 countries of the world consume less than 20 kg/capita/year, which is approximately 41 g of flour/day. A country that consumes 41 g of flour/day and fortifies its flour with 60 ppm elemental iron can potentially decrease its prevalence of anaemia by 1% (Nystrom, 2003).

In a country such as Nigeria, which only consumes 19.5 kg of wheat/capita/year, decreasing its anaemia rate by 1% through flour fortification could increase the nation's earning potential by 1.3 million USD yearly (Ross and Horton, 1998).

Globally, as many as 46 million cases of anaemia could be prevented if the countries that do not currently fortify began to fortify with iron (Nystrom, 2003).

7. Locating the Need: is Technical Fortification Support Needed?

Countries and regions of the world where the flour extraction rates have traditionally been high, ranging anywhere from 88% to 95%, are gradually shifting towards the production of refined flour.

As flour fortification is most effective in highly refined flour (Ranum and Wesley, 2003), there is a need for flour fortification programmes in these situations. This need has evolved gradually and remains largely unaddressed.

The vast majority of countries do not currently fortify flour, and the countries that do not fortify differ greatly in terms of their requirements, resources, economic condition and government policies.

The diversity among these countries therefore demands a unique approach to each solution on a case-by-case basis.

In general, though, these countries can be divided into three groups according to some common factors as described below:

• Highly industrialized countries which believe that their population is getting the necessary nutrients from other sources naturally and/or through vitamin/mineral supplements and therefore do not add anything to their flour.

• Countries that have the resources – technical as well as financial – for implementing fortification programmes but have not done so since they were not required to or were not aware of the benefits of fortification.

• Countries located primarily in less economically developed regions of the world, with limited resources and a relatively great need for fortification.

All three categories require very different approaches in order to be persuaded to consider implementation of the fortification programme.

It is crucial for technical information to be available and delivered to representatives of the grain processing industries in the countries of category 2 in general and category 3 in particular. This will help raise awareness and dispel any myths or fears about the technology of flour fortification.

In addition to technical and financial support, advocacy programmes carried out by politicians and senior development officers at appropriate political and administrative levels are important for all three categories.

National millers have also been an important influence in persuading countries to start national fortification (Darnton-Hill, 1999).

Sometimes it is very difficult for technical experts in those countries where flour fortification is practised, such as in North America, to fully appreciate the technical challenges associated with fortification. So when presenting the information, nothing should be taken for granted.

8. Reason for Fortification of Flour

When we talk about cereal crop based fortification, wheat flour and corn flour are natural mediums of delivery for the following reasons:

• Flour is consumed by a large segment of the world's population in large quantities.

• It is consumed in a wide range of popular forms such as bread, bagels, tortilla, cookies, noodles, steam bread, pasta, and macaroni.

• Flour is relatively inexpensive.

• Micronutrient premix can be added to form a homogenous product with flour because of flour's fine particle size. This would not be possible with a more granular food.

• Vitamins and minerals can be added to flour in the form of a premix.

In this way the general population can easily and inexpensively receive their critical vitamins and minerals by eating their normal food, be it pasta or bread or other flour-based products.

9. The Flour Mill as a Suitable Location

A flour mill is the logical location of choice to perform fortification for the obvious reasons mentioned above.

While there are other potential downstream flour processors that can also fortify flour or semolina-based products, several important factors explain why a flour mill is the most effective location for fortification. The following list provides the key points:

• Naturally adaptable process

• Large scale of production

• Technical knowledge, skills, and expertise of millers

• Familiarity with the process of dispensing powder-based flour improvers

• Suppliers to various end users.

10. Technical Capacity to Fortify

around the World Fortification is most easily done in roller mills, which have a daily capacity above 20 – 50 metric tons. However, many countries of the world have both a modern wheat milling sector with a capacity above these levels and a traditional cottage milling industry with a smaller capacity.

Cottage mills constitute a technical challenge to fortification, and technology is currently being developed to enable these mills to fortify (Ranum and Wesley, 2003).

As the ability of a country to fortify flour currently depends on the presence of a modern milling infrastructure, it is important to examine the milling infrastructure of various regions.

The percentage of a country's flour milled in each of these two sectors differs according to the region (Bagriansky, 2002). In general, the balance between these two sectors can be compared to either the situation in the South East Asian region or that in the regions of Africa and the Middle East.

In South East Asia where cereals are not traditionally grown, most flour consumed is imported and milled at a few large modern mills in each country. The cottage flourmilling industry is small to non-existent.

In the Middle East and South Asia, wheat is grown and has been a traditional crop for centuries. There are large numbers of mills in these areas, and while many are large and modern, there is a substantial cottage industry too (Bagrianski, 2003).

In India, for example, big modern mills process only 15-20% of the flour consumed.

Sub-Saharan and West Africa are an interesting mix of these two trends. In the 34 countries out of 45 for which information was available when this chapter was written, 28 have centralized milling amenable to fortification with a small number of large mills.

There is a wide range in the development of milling infrastructures, with 5 countries such as Gambia and Liberia having no flour mills, and three countries such as Kenya having large developed milling sectors with 10-20 mills (Nystrom, 2003).

More statistics are available at the FFI website www.sph.emory.edu/wheatflour/Main.htm.

11. Process Naturally Adaptable

The milling process is naturally disposed to fortification. As flour is produced and collected in flour conveyors, the required nutrients in dry powder form can be introduced and well mixed with the flour while it is carried over to flour scales and / or other equipment en route to flour bins.

The only additional equipment required is a powder feeder. In many cases powder feeders may already be present for the addition of powder additives for improving flour functionality.

|

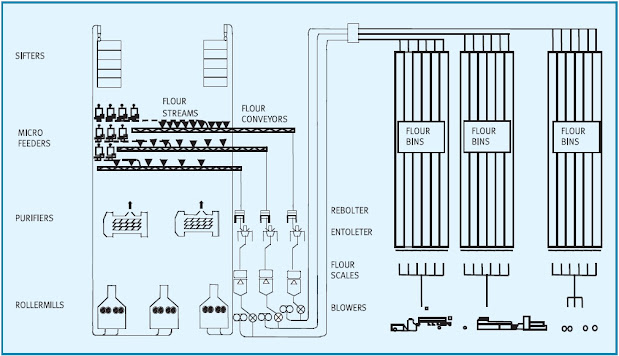

Fig. 105 is a diagram of a modern flour mill. The general configuration of most flour mills follows the same operating sequence.

There are flour mills in many parts of the world that may not necessarily have a comprehensive wheat storage and flour handling system, but all flour mills have a basic wheat preparation, milling and flour handling system.

The two main areas of a flour mill from a fortification point of view are the milling section and the flour blending and homogenizing system.

Although not every flour mill in the world has a comprehensive blending and homogenizing capability, there are a number of countries which do not currently fortify flourbut where such facilities are to be found and which are therefore technologically prepared for fortification.

Even if a flour mill does not have such a facility it can always use the flour collecting conveyor in the milling section to add the nutrients.

A reasonable mixing occurs in the flour conveyor, and potential for further mixing is increased with the use of an entoleter for infestation control and in further passage to flour bins through pneumatic lines under positive pressure.

Flour blending and homogenizing systems will be examined more closely in a later section. A large and modern mill that is required to cater to a diversified customer base with flour of consistent quality prepared according

to a specific recipe requires a comprehensive flour blending and homogenizing facility.

Such a facility comes with a macro and micro ingredient dispensing system and a good mixing and turnover system for flour homogenizing. This serves as an ideal system for flour fortification.

12. Large Scale of Production

The recommended minimum size of a flour mill is approximately 50 metric tons of wheat milling capability in 24 hours. This figure is based on an efficient capacity utilization relationship between various principal pieces of milling equipment, such as roller mills, purifiers and sifters.

From a technical point of view, therefore, capacities lower than this would mean under-utilization of some of the equipment. In order to achieve economies of scale the capacities have to be much higher, and the capacities of most mills are normally greater than 50 tons per day.

Therefore it is logical to fortify flour in a few large-capacity production facilities such as flour mills rather than in numerous smaller secondary processing facilities such as small bakeries or noodle shops.

13. Technical Knowledge, Skills and Expertise of Millers

Millers usually have a good educational and technical background. Their training prepares them to successfully overcome most technical challenges. Therefore, developing a system to incorporate flour fortification will be relatively easy for them when required.

Millers have the ability to analyze complex flow diagrams in order to understand and improve the quality of their production and implement any potential modification to expand and diversify production / quality requirements.

Wheat flour milling is known tobe one of the most challenging cereal processing technologies, primarily due to the presence of crease, which complicates the clean separation of bran and germ from the endo-sperm.

These must be separated to obtain optimum extraction of flour of high quality. Over the years millers have learned to meet this challenge, improving flour quality

and flour extraction levels.

14. Familiarity with the Process of Dispensing Powder-based Flour Improvers

Most millers are familiar with the process of adding macro and/or micro ingredients to the flour. They are familiar with the powder feeders and the mechanism of dispensing the powder into the flour.

Therefore it will be easier for them to introduce flour fortification. In addition, many mills add various additives in powder form to enhance the appearance of their flour and improve its functionality.

For such facilities it is only a matter of adding another feeder or preparing a premix with permissible ingredients.

15. Suppliers to Various End Users

While micronutrients can and sometimes are added in a bakery, it is much more convenient to fortify in the flour mill since a flour mill has numerous customers that include small bakers, large bakers, noodle manufacturers, pasta manufacturers and the retail business of household flour.

All of these facilities may be supplied by a few flour mills, as most flour mill capacities are much greater than the capacities of the ultimate users. Thus economies of scale are realized. Generally, flour mills are also equipped with laboratories for the detection of micronutrients in quality control.

16. Advantages of Flour Fortification

A flour mill benefits from flour fortification in a number of ways. These are:

• Increased value of the flour to the consumer

• Raised social profile of the milling industries of the world

• Recognition as a good corporate citizen

• Cost-effective reduction of hidden hunger in the population

• Beneficial use of foreign exchange if flour is imported.

17. Potential Concerns of Millers

Millers may have various concerns regarding the issue of flour fortification. This is more likely in the case of those millers who are contemplating fortification of flour for the first time. The following is a list of common concerns shared by millers in such situations:

• Cost of fortification

• Level playing field among competitors

• Quality implications

• Dependable supply of micronutrients.

18. Cost of Fortification

Estimated cost guidelines for fortification are available from suppliers of micronutrients and from the literature. Precise costs can be calculated when specific details are known.

Such specific details include the geographic location of the milling plant and how many micronutrients have to be added in what amounts.

Some markets may be more cost-sensitive than others. Like most other businesses, one may expect the milling community to be generally reluctant to embrace a voluntary fortification programme,

even if it is a simple one. Much of the skepticism is due to the fact that the cost of this additional process is not known for certain.

However, once it is recognized that the cost of fortification is quite reasonable and the technology very simple, then for many millers the resistance to the idea gradually disappears.

There are two main factors which determine cost of fortification per person and year: choice of the premix and per capita flour consumption.

The cost of simple fortification involving iron and folic acid is 4 to 5 U.S. cents per capita per year based on a per capita flour consumption of 250 g per day (Wylie, 2000).

Expanding the same fortification programme to include vitamins A, B1, B2, B3, folic acid and iron increases the cost to 45 to 55 cents per capita per year (Wylie, 2000).

A fortification programme involving vitamin B1, B2, B3 folic acid and iron costs around 10 cents per person based on a per capita flour consumption of 68 kg per year (AIC, 1998). These estimates provide a good indication of the cost of the premix (direct cost).

Freight and distribution costs must be added along with any other relevant expenses to achieve a region-specific cost figure.

Capital costs will include the purchase and installation of one feeder as several micronutrients are combined in a premix form, thus eliminating the need for several feeders.

Additional operating costs will consist of storage of the premix, maintenance of the feeder, and qualitative / quantitative tests for monitoring the presence of appropriate levels of micronutrients.

19. Level Playing Field

In most competitive environments millers consider it a risky proposition to participate in a voluntary flour fortification programme as they lose their competitive edge over those who refrain from participation. It is imperative that all millers in a country participate.

When everyone participates, as in countries with mandatory national flour fortification legislation, the additional costs related to fortification can be recovered and are insignificant in most situations.

A good example to support this is the price fluctuations of wheat, as many millers have experienced wide swings in wheat costs. However, since everyone has to pay the same price there is a proportionate and collective increase in the price of flour.

The price of wheat accounts for about 80% to 85% of the cost of a bag of flour.

20. Quality Implications

Millers planning to introduce a flour fortification programme may have concerns about whether some of the micronutrients added to the flour will have quality-related implications due to the nutrients' reactivity, or for any other reasons.

For example, in order to fortify flour with calcium in the UK, calcium carbonate is added. This has been the case for many years and the industry has adapted well to the method of determining flour colour rather than flour ash as a measure of refinement.

The industry has had to adapt because calcium carbonate increases the ash content of the flour appreciably, meaning that incremental small differences in ash content are less discernible.

However, when the same calcium carbonate is added to flour in hot and humid environments it reacts and alters the pH of the dough, interfering with the baking process. In such situations calcium sulphate is used instead.

Likewise, reduced iron is a popular iron source although it is magnetic and its bio-availability is only fair; however, it is very stable and does not promote rancidity.

Ferrous sulphate is used in a number of situations when non-magnetic type iron supplementation is required. Its bio-availability is very good but it does promote rancidity in the presence of fats during storage.

21. Dependable Supply

This requirement is self-explanatory. Obtaining a dependable supply of premix can, however, be a realistic concern for those who depend on importing the micronutrients from suppliers overseas; they do not want to overstock, but they cannot always count on just-in-time delivery.

However, reputable ingredient suppliers will not only guarantee a dependable supply but will also take responsibility for the consistent quality of their premix.

22. Accurate Dispensing of the Micronutrients

The reason why these nutrients are referred to as micronutrients is that they are required only in minute quantities, essentially in parts per million.

This necessitates a high degree of accuracy in adding the micronutrients to the flour, which in turn requires a well-functioning and economical dosing technology followed by an inexpensive but dependable system of detection.

It is understandable that for those who practise fortification or add flour improvers this is a routine and simple operation, but for those who are planning to carry out this process for the first time it can pose challenges.

While some challenges may be real, many others are perceived and can be addressed adequately through proper dissemination of factual information. In this respect the following need further elaboration and description:

• Feeders

• Carriers and physical properties

• Homogenizing

• Detection

22.1. Powder Feeders

Powder feeders are the first and foremost critical step in the process of fortification technology. There are many types of feeders that are available from a number of firms including ingredient suppliers and milling equipment manufacturers.

Different types of feeders include volumetric, gravimetric and loss-inweight feeders. Volumetric feeders are the most popular type of feeder used in North America.

|

| Fig. 103 : Power feeder (with kind permission from AIC Canada) |

One such feeder is described above (Fig. 103). As can be seen from the diagram, the float, indicating the level of the additive in the hopper, can be removed along with a lid that covers the top of the feeder. Additives are added from the top into the hopper.

The sides of the hopper, along with built-in guide vanes, flex with an oscillating motion to provide a constant agitation.

The powder flows to the feed rolls from the hopper. Stainless steel feed rolls are driven in opposite directions, facilitating discharge of the powder in a thin uniform layer over the width of the rolls.

This width of stream can be adjusted externally by means of a slide that can be moved along a graduated scale.

The feeder may also be provided with a variable speed motor, in which case the powder feed control is accomplished by varying the rpm.

When equipped with a variable speed drive using a DC motor, it provides a 4 to 20 milliamps signal that can be communicated through a controller for controlling the rate of addition from a remote point.

The powder feeder is interlocked to prevent any discharge when there is no flour or when the flour conveyor is not running.

22.2. Screw Feeders

These feeders are simple in design (Fig. 104). It consists of a large hopper that is filled with a micronutrient premix. A rotating screw is located at the bottom of the hopper. The rotation of the screw moves the micronutrient premix to an outlet where it is discharged into a flour conveying line.

The feed rate is controlled by a variable speed DC motor drive connected to the screw. A large conditioning screw or flexible pulsating plates near the bottom of the hopper maintain the premix in a free-flowing condition, thus avoiding bridging problems.

Advantages of this type of feeder are that it sustains a constant addition rate, has a wider range of delivery rates and hopper capacity, uses fewer mechanical parts and is less expensive to build.

It may be more sanitary and easier to maintain than the other types of feeders. It is the main type of feeder available as new equipment.

22.3. Carriers and Physical Properties

Since micronutrients are added in minute quantities (ppm), they are difficult to feed accurately and uniformly through a feeder. This becomes even more challenging when the output of a flour production facility is very small.

Therefore it is common practice to increase the bulk quantity of the premix containing the intended micronutrients by adding inert and free flowing material to help accomplish the uniform rate of addition.

In most premixes starch makes up the bulk of the material and is considered the carrier of choice. It is important for the premix colour to contrast as little as possible with the colour of the flour.

Even though the addition rate may be only 125 to 150 grams per ton (1,000 kg) of flour its colour may still affect the appearance of the flour. Most premixes are either yellow or white. Particle size is also considered to be very important.

In order to mix well with flour the particle size of the premix should be similar to that of the flour. At the same time, to ensure good free-flowing characteristics the particle size of the premix should not be too fine.

Wide differences in particle size lead to stratification. Irrespective of their origin, most flours have particles finer than 150 μm. Therefore, premix particle sizes are generally required to be 99% finer than 100 mesh (equivalent to 150 μm).

Micronutrient premix is added well before the flour is rebolted (sifted) for either bulk delivery or packing. Although nylon sieves coarser than 150 μm are generally used for rebolting, 150 μm sieves are used in some cases.

If the premix particle size is not in compliance with size specifications the premix may be sifted out.

22.4. Homogenizing

In North America most feeders are situated directly on a flour conveyor. As the flour is conveyed to the outlet it gets mixed with the various additives that continue to discharge from the feeders at desired preset quantities.

The longer the flour conveyor, the more thorough will be the mixing. Feeders are therefore located on the conveyor in such a way that following the discharge of the powders the length of the conveyor is sufficient to allow a good mixing action.

In those plants where feeders are located away from the flour conveyors and therefore a blowing line is used to transport the microingredients into the conveyor, the lines are connected in such a way that there is enough conveying length to permit good mixing.

The flour dropped down the spout is allowed to pass through a flour rebolter (small sifter) followed by an entoleter. These are used as a precaution to prevent any infestation from devel-oping and propagating.

The entoleter has a rotor that consists of two discs separated by a number of concentric spindles. The rotor runs at a high speed of 2,900 rpm to 3,600 rpm within a conical casing. This facilitates the vigorous dispersion of the flour particles, allowing further mixing.

So in those facilities where the flour conveyor used is small, this system helps to compensate somewhat. Flour from the entoleter then passes through a flour scale and enters a positive-pressure air line through an airlock.

As the positive pressure blows the flour through the air line into the bin, the additives and the flour particles are homogenized further. The illustration in Fig. 105 shows the method described above.

|

| Fig. 105 : Continuous flour fortification in the mill |

Batch mixing of flour ensures even more thorough and intimate mixing of flour with macro and micro ingredients and various other additives. This method is illustrated in Fig. 106.

|

| Fig. 106 : Flour fortification by batch blending |

23. Detection

As we have already said, detection is an important aspect of flour fortification. Overdosing flour with micronutrients is not only unnecessarily expensive but also undesirable.

When fortification is carried out under US federal law, flour milling facilities are required to meet appropriate levels to fulfil their legal obligation. For all of these reasons it is important to conduct detection tests periodically.

If the feeder discharge rate is monitored on a regular basis and the flour output does not change, then the dependence on the detection test is not as great.

Over a prolonged period of time the consumption of the micronutrient premix and flour production quantities give a more accurate picture of the level of fortification used.

Although this gives a more accurate figure of usage on average, it does not mean the rate of addition was consistently uniform over this period of time.

In general, the possibility of overtreatment is unlikely, as no business entity would be prepared to waste premix costs over an extended period of time and let it remain undetected.

Detection tests are a lot more critical in an environment where fortification is being introduced through legislation and many people perceive a few flour mills to be non-compliant, or where implementation of a voluntary programme is claimed by most milling companies but followed by only a few.

Detection of some micronutrients can be rather involved as compared to others. So in a situation where a combination premix is used it is economical and logical to test for the micronutrient that is easy to detect.

For example, in a simple fortification programme involving iron and folic acid it is sensible to conduct detection for iron, as the detection test for folic acid is much more involved.

24. Conclusion

The International Association of Operative Millers (IAOM) in conjunction with FFI has formed a Technical Training and Support Group in order to communicate globally the hows and whys of flour fortification described above.

The Group acts as an umbrella organization to support fortification education in milling schools around the world.

Flour fortification "creates something of enduring value", in the words of Philip Purnama, owner of Bogasari flour mills in Indonesia and a speaker at the International Grains Conference in London in 2003 (Purnama, 2003).

That enduring value consists in gener-ations of children who grow up smarter and stronger than their parents before them, able to build a better life for themselves and their families.

Post a Comment