8. Optimizing Bread Rye Quality

for the Market

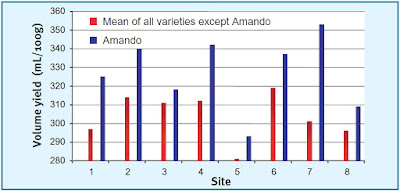

On the basis of the work of Drews (1971a, b) on the introduction of a

certain buffer for swelling curves, the Rye Viscosity Test (RVT) was developed.

The test makes it possible to obtain some important additional information in

about 30 to 45 min, a time that can usually be spared when rye is taken in, for

example by a mill. Because of the small sample quantities it requires, the RVT

can also be carried out by breeders as a selection criterion. The RVT is

currently undergoing practical trials, and over 100 samples have already shown

a certain correlation with baked volume. At the same time it has yielded

further proof that some lots with higher Falling Numbers may have good

inflation potential. In the past, only the Amando variety was known to have

this property. When compared with other varieties it always produced the

largest bread volume, independently of the site on which it was grown and its

Falling Numbers and Amylogram values (Fig. 96).

|

| Fig. 96: Volume yields (rye/sour dough baking tests) of flours from

the rye variety Amando compared with flour from other varieties (mineral

content approx. 1% of dry weight; 1998 harvest) |

Because of the baking results obtained over the past decades, the

author considered it necessary to modify the current practice of assessing rye

solely according to the criteria of the BSA's descriptive list of varieties,

with steadily increasing results for 1000-grain weight, crude protein, Falling

Numbers and Amylogram values. More and more, rye lots are being recommended

whose high rheological Falling Number and Amylogram values are outside the

optimum range for good rye bread quality. One way of achieving a more accurate

prediction of bread quality is to carry out a standard baking test and determine

dough yield, the degree of leavening, the volume of the bread and the

elasticity of the crumb as quality criteria.

9. Current Rye Research and Processing

Properties

Compared with other cereals, rye has only brief secondary dormancy. So

under unfavourable weather conditions germination may start again, even in the

blade, soon after the morphological ripening of the grains. If germination is

visible it is known as visible sprouting. To the extent that they can be

detected analytically, the preliminary stages of germination are described as

latent sprouting.

Such germination leads to increased enzyme activity, which in turn

results in the breakdown of components of the cell walls and also stored

substances. As sprout-damaged rye is considered unsuitable for bread-baking,

this presented a challenge to breeders. In the past, α-amylase activity was

generally measured as a selection criterion; now the assessment is almost

always made on the basis of the Falling Number.

In rye research and analysis the pentosan complex used to be given

greater attention than the structure of the starch. But the following starch

ratios are considered relatively constant. At the time of ripening, the cereal

starch consists of about 25% amylose and 75% amylopectin. The starch grains can

be divided into two types: larger, lentil-shaped bodies with a diameter of

about 40 mm – "A-types" – and smaller, more spherical

"B-types" with an average diameter of about 10 mm. Besides these

there is a fluctuating but nevertheless appreciable percentage of medium-sized

starch grains. The exact ratio of A to B types of starch grains in rye is not

known. Whereas about 90% of the starch grains in wheat are of the B type, the

percentage of these smaller grains is thought to be somewhat smaller in rye. This

may have significance for resistance to sprouting, since the smaller B starch

grains and also the medium-sized types are more readily attacked by amylases

because of their larger specific surface area. But in spite of their larger

number, the percentage of smaller starch grains in the overall mass is fairly

small in terms of volume and weight. Dreisörner (2002) also found a

considerable proportion of medium-sized starch grains that increases with

breeding.

The starch is broken down by hydrolases, mainly through the combined

activity of the α- and ß-amylases in the cereal grains. When the grain is

stored in the field, especially, α-amylases from moulds and bacteria on the

ears and grains may have this effect. In particular the dextrins formed by

α-amylase may then be exposed to further attack by ß-amylase or

amyloglucosidase.

The α-amylase newly formed during germination seems to be an important

factor influencing processing quality. Its concentration increases during

ripening and reaches the highest values if latent or visible sprouting occurs.

A further breakdown is possible during gelatinization of the rye starch in the

baking process, in the presence of sufficient water, high temperatures and a pH

that is not too low.

There is an increase in temperature even when the grain is dried, but

little moisture is present. Such tempering has also been found to reduce the

tendency to gelatinize. This means that the water content of the grains is

extremely important for the activity of the enzymes. Their effect seems to be

greatest at a grain moisture of 30 - 40% and is largely prevented at values

below 20%.

Determination of α-amylase is a complicated matter. It is measured

with a large excess of water and often with the addition of a foreign

substrate, e.g. coloured starch. So determination of enzyme activity is even

farther removed from the conditions of bread-making than the Falling Number or

Amylogram method. However, the effect of the enzymes during processing is more

important than the enzyme activity that exists in absolute terms.

The grains contain a total of about 7 - 10% pentosans. Like proteins,

they are one of the swelling substances of the rye, but unlike protein they are

not considered to be energy reserves. The insoluble pentosans are a component of

the cell walls. The ratio of the soluble pentosans (part of the content of the

cell) to the insoluble pentosans (constituents of the cell walls) has yet to be

determined. Larger percentages of insoluble pentosans are indicated by

increasing Falling Numbers of the flour, whereas larger percentages of soluble

pentosans seem to affect the peak values of the Amylogram but not the Falling

Numbers. The pentosans are readily attacked even at dough temperatures, so it

makes sense from the technical point of view to determine them. The behaviour

of the swelling substances of the rye during processing (e.g. viscosity of the

dough) is therefore determined by the pentosan and protein content and its

susceptibility to attack.

|

| Fig. 97: Flow diagram of the Rye Viscosity Test |

Certainly an adequate reduction of viscosity has to be ensured in

order to achieve the required attributes of the bread. This complex will

doubtless become an important feature of technical rye research in the near

future, especially as some rye varieties seem to react more sensitively than

others to an overdose of water or cause greater softening of the dough in spite of high Falling

Numbers, as swelling curves and the new Rye Viscosity Test (Brümmer, 2002) show

(Fig. 97). Successful breeding in respect of yield and the reliability of the

yield is making rye more attractive again as a crop. Both of these factors and

also resistance to sprouting still depend chiefly on the weather, harvesting

techniques and post-harvest treatment and less on the properties of a

particular rye variety. In Germany, the

characteristics of different rye varieties were only apparent under very

uniform weather conditions. But in spite of fluctuations, years of quality

testing of milled rye products have revealed certain trends (Fig. 98).

|

Fig. 98: Comparison of the analytical data for the German rye harvests

of the years 1983 – 2002 (rye flour types 997/1150)

|

The past few years, including the harvest of 2001, have almost made us

forget that rye is still susceptible to sprouting. Although the rye of 1993 and

2002 broke down rather more readily, the commercial flours were drier when

baked than ideal bread flours. This raises the question as to how much

"sprouting" is necessary for baking bread and other, smaller products

containing rye.

To answer this question, bakers have mainly considered the Amylogram

and the baking test, complemented by the Falling Number, maltose content and

swelling curve. The Falling Number is a quick determination method, but it is

subject to greater fluctuations in respect of suitability for processing than

the peak Amylogram temperature, for example.

|

Fig. 99: Processing quality and results of indirect methods for rye:

rye Amylogram – peak temperatures and Falling Numbers and expected suitability

of the milled products for baking

|

Fig. 99 is an attempt to correlate the results of indirect methods

with good bread quality. The "quality window" in the centre of the

diagram shows the analytical ranges especially recommended for making bread and

other small products containing rye. Outside this frame the uses of other ryes

that break down more readily or less easily during baking are shown. Ryes that

break down very readily should only be used for coarse meal. Milled products

that reach into the dry baking range for flours of the types 997/1150 may be

regarded as particularly suitable for fine whole meal or wholemeal flour. Of

course lots of this kind can also be used for making special baked products

such as crispbread or to improve lots of rye whose substrate is too susceptible

to attack or which show too much enzyme activity (mixed rye).

At present, millers are still very hesitant to grind rye with low

Falling Numbers and Amylogram values in the usual way – probably a result of

bakers' fears. But some bulk buyers have now recognized the opportunities

offered by such rye properties for enhancing the quality of their bread.

Post a Comment