1. Introduction

Chinese steamed bread is a fermented wheat flour product that is cooked by steaming in a steamer. It is said to have originated in China during the Han Dynasty, over 1,500 years ago.

Over the centuries, steamed bread has spread from China to other Asian countries, and it has played an important role in the diet of many Asians. Today, steamed bread accounts for about 60% of total flour consumption in northern China and 20 - 30% in southern China.

The percentage of flour used for steamed bread is 5 - 15% in other parts of Asia, and it is increasing rapidly in some Asian countries such as the Philippines.

Chinese steamed bread is often made from a wheat flour of low or medium protein, depending on the type.

The preparation process is similar to that of western-style pan bread, but the final product is steamed, not baked in an oven, so there are some differences in appearance and shape between pan bread and steamed bread. Steamed bread is white in colour and has a soft, shiny surface.

The common types of steamed bread weigh about 30 - 120 g and are either pillow-like or round in shape (Fig. 195 and Fig. 196).

|

| Fig. 195 : Pillow-shaped steamed bread |

|

| Fig. 196 : Round steamed bread |

The original steamed bread was a filled bread, but it has gradually changed in the course of time. Nowadays, "steamed bread" always means unfilled bread (called mantou). Filled steamed bread is now called steamed buns (baozi; Fig. 194).

|

| Fig. 194 : Steamed buns made in the laboratory (source: H. Moegenburg, Muehlenchemie Asia Pte. Ltd.) |

Steamed buns are popular in southern China, Taiwan and Southeast Asia. The fillings for the steamed buns can be sweet or savoury.

Typical sweet fillings include various bean pastes mixed with sugar. Savoury fillings include chopped vegetables, minced meat and seafood, or a combination of these ingredients.

2. Types of Steamed Bread

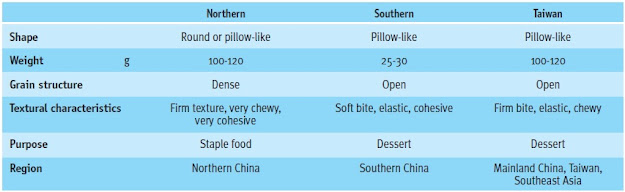

There are three main types of steamed bread consumed in China: northern type, southern type (Guangdong), and Taiwan type. The main differences between the three are outlined in Tab. 103.

|

| Tab. 103 : Characteristic differences between the three types of steamed breads |

The traditional northern steamed bread, eaten as a main meal by the people in the north of China, used to have a very chewy and elastic bite. Shangdongstyle steamed bread (Chiang mian mantou) is a typical northern type.

In some areas, however, the textural characteristics of northern steamed bread have changed somewhat and become more like the southern type, i.e., slightly softer than the typical Shandongstyle because the bread is no longer considered a main meal by many people.

Southern type steamed bread is often referred to as Guangdong type and is widely consumed in the south of China. Its texture is softer and its taste sweeter than that of the northern type, and so it has long been popular as a "dim sum" item in Chinese restaurants.

Taiwan type steamed bread is a combination of the northern and southern types, so it has the combined textural characteristics of both. It is less sweet than the southern type and less chewy than the northern type.

This type of steamed bread is widely consumed in Taiwan and Southeast Asia. It is also gaining popularity in Mainland China because of increased migration between the north and south of the country.

3. Formulation

Chinese steamed bread formulas differ according to type. A typical formula for each type is shown in Tab. 104.

|

| Tab. 104 : Typical steamed bread formulas (%) |

The northern-type steamed bread has the simplest formula containing only flour, water, and yeast. Both the southern type and Taiwan type contain sugar, shortening, and sometimes baking powder, all of which are absent from the northern type.

In the southern type the amount of sugar added is much greater than in the Taiwan type. The water added varies according to the flour used and the type of process, and can be estimated by Farinograph water absorption.

Each type of steamed bread requires a different type of flour. Generally speaking, the southern type requires soft wheat flour, and the northern and Taiwan types of steamed bread need medium-protein hard wheat flour.

Besides these basic ingredients, other ingredients such as milk powder, soy flour, yeast food and alkaline salt are added to steamed bread to modify the formula, process, colour, texture, and flavour.

4. Wheat Flour for Chinese Steamed Bread

Since Chinese steamed breads were introduced from China to other Asian countries, they have evolved into many forms and adapted to local preference. As a result, the demand for steamed bread flour has increased over the years.

For instance, only 5% of the total flour is currently used in steamed bread production in the Philippines, but according to an industrial source the amount is expected to double within the next two years.

Other countries in the region are experiencing a similar trend. Steamed breads have now become a popular item in many Chinese restaurants in North America.

Flours used for making steamed bread have variable quality characteristics because each steamed bread type requires its own specific flour quality. Tab. 105 lists some basic flour specifications for the three types of steamed bread.

|

| Tab. 105 : Basic flour quality specifications for Chinese steamed bread |

The main specifications are flour protein, ash and wet gluten content, and also Farinograph dough mixing properties. To achieve the desired eating quality and good appearance, protein content varies according to the steamed bread type.

High-protein flour generally results in a firm-texture product, but it often causes wrinkles on the skin because of excessively strong dough properties.

Because of the textural preference and different formulas, Taiwan type steamed bread requires higher protein flour (hard wheat flour) than both the northern type and the southern type. Southern type steamed bread uses a lowprotein flour (soft wheat flour) to give the desired soft texture.

Flour ash content has been rated as one of the important steamed bread flour specifications because it has a negative effect on colour and specks.

Most flours for making steamed bread require an ash content of less than 0.45% (14% m.b.), but premium quality steamed breads are often made from flours with 0.4% or less ash (14% m.b.).

Dough properties measured by the Farinograph are often specified by end-users because they are useful quality indicators for the finished product. Farinograph water absorption determines the amount of water needed for a flour to be optimally processed into steamed breads.

The estimated water addition level in steamed bread is 75 - 80% of the flour's Farinograph water absorption, depending on the steamed bread type. Ingredients such as sugar and shortening affect the amount of water needed. Farinograph stability time is a good indication of dough strength.

A dough that is too strong or too weak for a particular steamed bread formula is not likely to produce the desired quality.

In addition to these basic quality parameters, others such as the Falling Number, starch damage and the Extensograph are also viewed as important quality indicators. Flour milled from a sound wheat (Falling Number more than 300 s) is necessary for making good quality steamed bread.

A flour of high amylase content tends to produce steamed bread with a sticky texture. The flour starch damage level is often controlled at below 8%, because damaged starch causes sticky texture and accelerates starch retrogradation during storage.

Extensograph parameters measure the balance of dough extensibility versus elasticity. Too much elasticity causes difficulty in steamed bread processing and shrinkage of the finished product, while too much extensibility results in a flat-shaped product and weak resistance to bite.

5. Ingredients and Functions

Flour, water, and yeast are the basic ingredients of Chinese steamed breads. Many other ingredients such as sugar, shortening, baking powder, salt, alkaline salts and emulsifiers are often included by manufacturers to improve the quality of finished products or extend the product lines (Tab. 106).

|

| Tab. 106 : Typical steamed bread ingredients and functions |

6. Production

Traditionally, Chinese steamed bread was made at home by hand, and this is still the case in many parts of Asia. However, in the past two decades steamed bread has been mass-produced as more and more people prefer the convenience of commercial products.

Among all of the preparation methods available, three main methods are commonly used: the sour dough method, the sponge and dough method and the straight dough method (Fig. 197).

|

| Fig. 197 : Outline of Chinese steamed bread making procedures (A) Sour dough method (B) Sponge and dough method (C) Straight dough method |

6. 1. Sour Dough Starter Method

A sour dough starter is usually the remains of the fermented dough batch from the previous day. This method is traditionally used in homes or in small shops because sour dough is easy to prepare and there is no need to buy yeast.

The starter must be thoroughly mixed with water before being added to the flour to prepare the dough. In this procedure, flour is mixed with 10% sour dough starter and water for 5 - 10 min. The dough is fermented for 3 h at 26 - 28 °C and 75% relative humidity (RH).

In the sour dough starter, the yeast naturally present is "contaminated" with the bacterium Lactobacillus

spp., which causes the fermented dough to sour (pH 3.7 - 4.0). So after fermentation an alkali (40% Na2CO3 solution) is needed to neutralize the sour dough until the pH reaches 6.4 - 6.7.

The amount added is usually about 0.5% of the flour weight. The neutralization step is considered to be crucial for good quality steamed bread. If the dough is over-neutralized, the steamed bread will become yellow or dark in colour with a strong alkaline flavour.

If the dough is under-neutralized, the steamed bread has a sour smell and taste, small volume, poor appearance and a dense structure.

The addition of alkali also assists in proofing as it neutralizes acids produced by lactic acid bacteria during proofing and allows the production of carbon dioxide and water by yeast. The neutralization process can be done either by hand or by a mechanical mixer.

Further mixing may be required for some types of steamed bread when the neutralization process is complete. After these steps, the dough is sheeted to develop the gluten network and make it smooth.

The dough sheet is then rolled into a long cylindrical shape either by hand or by machine, divided into pieces of a specified weight (100 - 130 g), and formed into a pillow-like or round shape as desired.

Finally, the steamed bread dough pieces are proofed for about 30 min (32 - 36 °C, 75 - 80% RH), and steamed for about 15 min in a steamer until fully cooked.

6. 2. Sponge and Dough Method

The sponge and dough method is a traditional steamed bread preparation procedure. The process steps include mixing of the sponge, fermentation, dough mixing, sheeting, moulding, dividing, proofing, and steaming.

In preparation of the sponge, 80% of the flour is mixed with yeast and water. Either fresh or dry yeast is used. After about 1 hour of fermentation at 32 °C and 80% RH, additional flour and other ingredients are added and re-mixed to produce dough.

After that, the dough is processed into steamed bread as previously described. The sponge and dough method has two advantages in production.

The first is its tolerance to a flexible fermentation schedule from batch to batch, and the second is that this process gives steamed bread a fine cell structure and well developed flavour. However, the disadvantages are that it requires more work, more space, and a longer production time.

This method is still used by some commercial manufacturers because of a better final product and processing flexibility.

6. 3. Straight Dough Method

The straight dough method is much simpler than the other two and is therefore widely used in industry because of this simplicity and the short process time. In this procedure, flour and all other ingredients are mixed together to make a dough.

The dough is then processed as described in the first two methods. The proofing time is about 40 min, which makes this method much shorter than the other two. As a result, the method is quite sensitive to process timing between batches in commercial production.

For example, the dough of some batches may receive optimum fermentation while others become over-fermented or underfermented if the operation schedule is not well controlled.

Moreover, the grain structure of the finished product is not as fine as that of the sponge and dough method and the steamed bread lacks the characteristic flavour derived from traditional methods.

One of the key steps in manufacturing a good quality steam bread is to control its proofing process. The degree of proofing affects the shape, colour, texture and flavour of the finished products. Proofing temperature and relative humidity determine the proofing time.

A typical proofing temperature is 32 - 37 °C and relative humidity is 70 - 80%. In most cases the optimum proofing time is determined through experience by viewing and touching the rising dough pieces.

The rule of thumb is that when steam bread dough is optimally fermented it is shiny in appearance and very springy when the surface is touched. However, this empirical way of judging the optimum proofing time lacks consistency.

To solve this problem, a standard procedure using volume control was developed by G.G. Hou to determine the optimum proofing time when the straight dough method is applied. In this method, 25 g of steam bread dough is filled into a 45 mL plastic centrifuge tube (3 cm in diameter).

The dough volume is approximately 21 - 22 mL. After proofing, the final dough volume is 38 mL for southern type steamed bread and 45 mL for northern and Taiwan type steamed breads.

The manufacturing process and quality of steamed bread is controlled much more efficiently by this standardized procedure. Each laboratory may need to determine its own optimum volume increase if different tubes are used.

7. Quality Evaluation

The evaluation of steamed bread usually includes processing performance, volume, external characteristics, internal characteristics, eating quality, and flavour. Tab. 107 is a typical steamed bread evaluation worksheet for the straight dough method.

|

| Tab. 107 : Chinese steamed bread evaluation worksheet (straight dough method) |

In this evaluation method, the total steamed bread score is a combination of process score (15%) and product score (85%).

Steamed breads made by other methods may use a slightly different evaluation worksheet. Within the categories "process quality" and "product quality" there are a number of evaluation items.

The performance of flour in the process of steamed bread production is of importance to steamed bread manufacturers because it has an impact on end-product quality.

The ease of handling and the consistency of the processing behaviour of flour in an automated processing environment determine the acceptance of a particular flour in the manufacture of steamed breads.

|

| Tab. 108 : Chinese steamed bread processing evaluation |

Evaluation criteria for each processing step are described in Tab. 108. As pointed out previously, proofing conditions are one of the critical control points in steamed bread production.

|

| Tab. 109 : Chinese steamed bread quality evaluation |

Evaluation criteria for steamed bread quality are described in Tab. 109. In the evaluation of the product itself, specific volume (mL/g) is often considered an important quality parameter because the larger specific volume is more favourable.

However, each type of steamed bread has certain ranges for specific volume due to differences between formulas. Southern type steamed bread usually has a larger specific volume than the northern type because of its open crumb.

Steamed bread should be springy and can rebound after compressing. Steamed bread with desirable external characteristics should have :

• a smooth and shiny surface with no yellow spots;

• symmetrical shape;

• large volume; and

• white and bright colour.

Common problems include wrinkles, blisters, yellow spots, patches of ungelatinized dough, a flat top and a flat shape (too much spreading). Desirable crumb is white, moist and springy. It should also have a fine and uniform grain cell size and pattern.

Dry crumb and/or very tight and dense cells are considered undesirable. Fig. 198 shows examples of good quality and poor quality steamed breads. The poor quality steamed bread has a shrunken top that is usually caused by excessive gluten strength.

The crumb grain has holes and is off-colour in the centre; this may also be caused by too-strong protein. If the dough is too strong it cannot be processed optimally into a tightly rolled cylinder.

Eating quality varies with the type of steamed bread and local preference. Steamed bread can have firm bite or soft bite depending on whether it is northern type or southern type. The northern type is much chewier and more cohesive than the southern type.

The chewiness of Taiwan type steam bread falls somewhere in between these two types. No steamed bread should be sticky when chewed in the mouth. It is also important for the steamed bread to have a characteristic flavour and smell.

8. Factors Affecting Chinese Steamed Bread Quality

Factors that affect steamed bread quality can be categorized into three main groups: flour source, ingredient course, and process course (Tab. 110). There are numerous variables in each category, but flour-based variables are primary causes and deserve particular attention.

|

| Tab. 110 : Factors affecting Chinese steamed bread quality |

As previously discussed, protein content, ash content, and protein quality as measured by the Farinograph are useful flour quality indicators for steamed bread quality. Flour protein content affects steamed bread volume.

As the flour protein is in the range of 6 - 11%, there is a positive correlation between steamed bread volume and protein content. However, if the flour protein is too high (more than 12.5%), the bread tends to shrink on the surface and takes on a dark colour.

If the flour protein is too low, steamed bread lacks a good bite and often becomes sticky. Flour particle size may affect the water absorption rate and the speed of dough formation.

Within the ingredient source, the sugar addition level appears to be very important in modifying steamed bread volume and texture. When a larger amount of sugar is used, the bread becomes larger in volume and has a softer texture.

The use of shortening not only modifies the texture of the bread but also reduces the amount of water added in the formula. As in western bread making, an emulsifier improves the crumb grain texture and slows down starch retrogradation.

Flour improvers, particularly oxidizing agents and enzymes, are gaining increasing importance as the demand for flour with constant high level performance increases.

Enzymes from microbial sources, e.g. α-amylase, hemicellulase, lipases and oxidases, improve the dough handling properties and result in larger volume yield (chapter Steamed Bread - Flour Treatment for Specific Applications).

Some hemicellulases improve the brightness by a physical effect: they result in a finer crumb structure which reflects more light than a coarse structure with more "shadow zones".

Lipase also improves the brightness by creating free fatty acids which are more easily accessible to flour lipoxygenase and oxygen, particularly when a dough sheeting step is involved. The resulting hydroperoxides oxidize flour pigments in turn.

All enzymes mentioned above also improve crumb softness (due to larger volume and finer pore walls) and intermediate heat-stable amylases are even able to reduce the staling rate.

The process behaviour of steamed bread is critical to the success of large-scale production and the quality of the end product. An optimum water addition level appears to be the most important factor because it affects the remaining process steps.

Mixing helps gluten development. Sponge fermentation affects product volume and flavour. In the case of the sour dough method, neutralization of the sour dough improves the taste, volume, appearance and structure of the finished product.

Sheeting has a great impact on skin smoothness and crumb structure. Proofing time is associated with flavour development and crumb structure. It also affects bread volume and spread. Steaming gelatinizes the starch and influences appearance and eating quality.

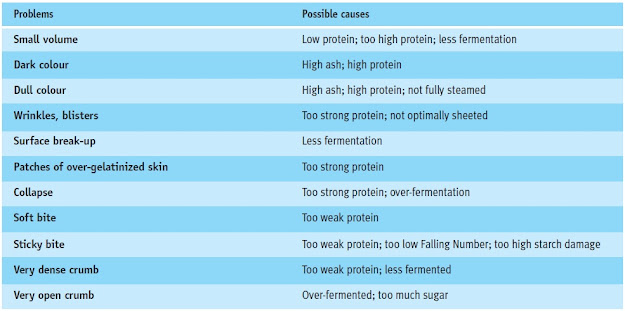

Tab. 111 summarizes the common problems that occur in steamed bread production.

|

| Tab. 111 : Common problems associated with steamed bread production |

9. Steamed Buns (Filled Steamed Breads)

|

| Fig. 199 : Laboratory steam buns (the Philippines); (source: T. Schramm, Mühlenchemie GmbH) |

Steamed buns are popular in southern China and other parts of the World (Fig. 199). There are many varieties of steamed buns with differences in sizes, textures, shapes, and fillings. Steamed buns are usually made from southern type dough.

A typical formula specifies: medium protein hard wheat low extraction patent flour, 100%; instant yeast, 1%; baking powder, 3%; salt, 1.5%; sugar, 14%; shortening, 7%; and water, 48% (variable).

After mixing all the ingredients together with the flour, using a straight dough method, the dough is fermented for about 1.5 h at 32 °C and 82% RH. The fermented dough is sheeted until it becomes smooth.

The dough sheet is then hand-rolled into a cylindrical shape and cut into small pieces (50 g). These dough pieces are rounded by hand and left to rest for 10 min in the fermentation cabinet (32 °C and 82% RH).

After resting, each dough piece is flattened with the palm and sheeted into a 7.5 cm circular piece by rotating and making the edges thinner than the centre. About 1.5 tablespoons of filling is placed in the centre of the round, flattened dough piece.

The filling is sealed within the dough by pinching and pleating the edges of the dough together. Each filled bun is placed on a rectangular wax paper in a steamer and proofed for 45 min (32 °C and 82% RH).

The buns are steamed for 10 min or until fully cooked, and this is when the steamed buns are best served. They can be stored in a refrigerator or freezer and later heated in a steamer before serving.

10. Steamed Bread Outside Asia

Although steamed bread is considered an Asian food, similar products can be found in other parts of the world.

In Germany (particularly the south), Austria and the Czech Republic, they are traditionally served as a dessert or a sweet main course, with stewed fruit, jam, sugar, cinnamon and other spices.

Steamed, frozen bread has recently established itself as a convenience food in German freezers, and many variations can be found in the supermarkets.

The main differences between Asian and European steamed bread are the higher amount of salt added to the western version and the use of fat (Tab. 112).

|

| Tab. 112 : Comparison of dough composition for Chinese and European steamed bread |

The flour is mostly prepared from European bread wheat, comparable to weak hard wheat varieties. If the gluten is too strong, the buns tend to break at the surface.

11. General Discussion

Steamed bread has been considered a staple food in northern China, just like baked bread in the diet of the western countries.

However, steamed bread is very different from baked bread in that it is cooked by steam at atmospheric pressure, and thus the cooking temperature is much lower than for baking bread in an oven. Steaming results in a thin soft crust without a browning effect.

During the bread baking process, Maillard reactions take place, forming a golden yellow crust. This reaction also causes the loss of soluble amino acids (mainly lysine), which reduces the nutritional value of the bread.

In this respect steamed bread is more nutritious than baked bread. Furthermore, acrylamide is formed as a secondary product of the Maillard reaction during baking, but not during steaming.

Nevertheless, the present steamed bread process has certain limitations. Firstly, steamed bread is best consumed warm, which is not as convenient as baked bread that is ready to eat at any time.

Secondly, steamed bread loses its flavour and physical and eating quality once it has been re-steamed. Thirdly, steamed bread has a higher moisture content because of steaming, so its shelf-life is shorter than that of baked bread.

All these limitations have restricted the further development of large-scale production. How to solve these problems effectively by applying the advanced technology currently used in other food manufacture remains a challenge for the future.

Do you have information about glutenfree steamed bread. More and more people are sensitive to gluten, I would like to experiment, but I don't want to waist any food as well. Since steamed buns is also made with cakeflour which contains little and some cakes are also made of glutenfree ingredients, it should be possible isn't it?

ReplyDeletePost a Comment