Dampening,Tempering and The Second Cleaning Section Wheat

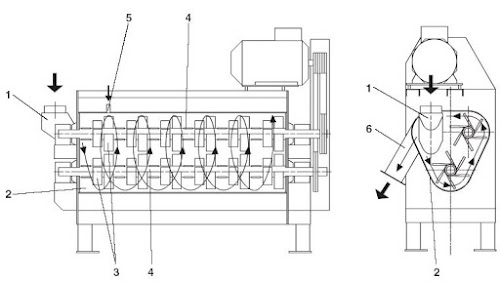

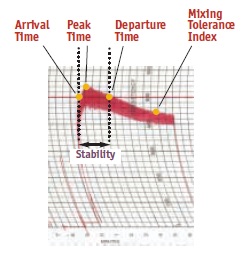

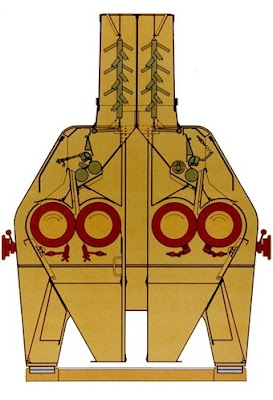

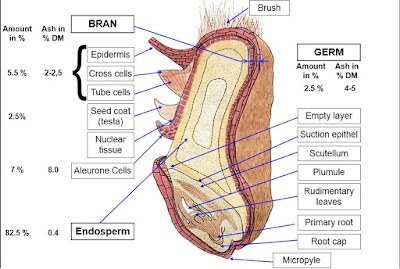

By : Novozymes and Buhler Dampening and Tempering Wheat Dampening and tempering of wheat helps : • Make the bran tough and elastic • Mellow the endosperm • Achieve the correct flour moisture content • Maintain constant grinding conditions During dampening or tempering , the grain enters the dampener through the front-end inlet. Together with the separately added water, the grain undergoes an intensive intermixing and water penetration by the bi-rotor whirling system. The thoroughly dampened grain is discharged from the machine through the tangential outlet to the dampening or tempering bins. Cross Section of dampener (Picture is courtesy of Buhler AG, Uzwil, Switzerland) Selection of the moisture content of wheat at the first break depends on various factors. If we have to produce flour with low ash content, it would be better to run with higher moistures. This is especially the case with the hard wheat varieties. Here, we have a ra...